English ![]()

Tel: +86-13732621090

Email:yewu001@yushengdz.com

4F, No.68, Huian Road, Xukou Town, Wuzhong District, Suzhou, Jiangsu, China, 215105

Views: 0 Author: Site Editor Publish Time: 2025-07-25 Origin: Site

Litz wire cuts down AC losses and makes things work better.

It helps transformers, motors, and high-frequency circuits get smaller and work better.

Litz wire has many thin, insulated strands twisted together. This helps stop energy loss in high-frequency devices.

It lowers AC resistance by fighting skin and proximity effects. This helps devices stay cooler and use less power.

Litz wire is used in electric vehicles and wind turbines. It is also used in 5G networks and other new technology in 2025.

Picking the right strand size and insulation is important. You need to match them to your frequency and temperature needs for best results.

New materials and ways to make Litz wire help it work better. These changes make it more eco-friendly and save money for the future.

You might ask how litz wire is not like regular wire. Litz wire is a special cable made from many thin copper strands. Each strand has its own enamel coating for insulation. The strands twist or braid together in a certain way. This pattern lets each strand move from the inside to the outside. Because of this, the current spreads out more evenly. This means there is less energy loss, especially at high frequencies.

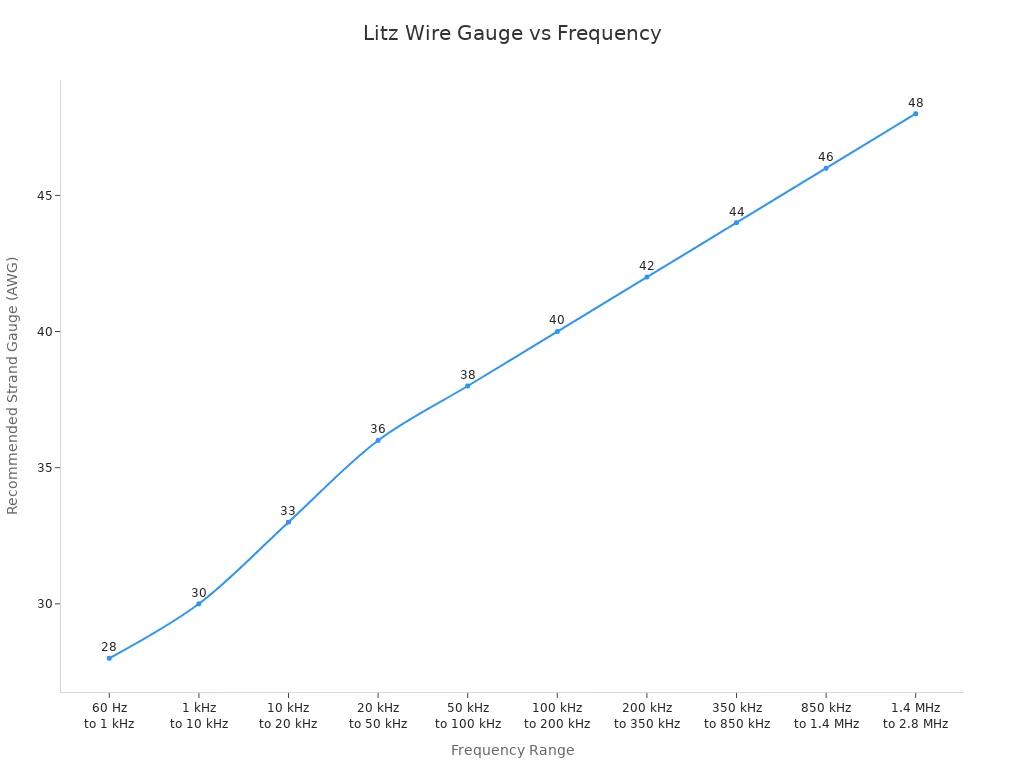

Groups like New England Wire Technologies say litz wire is a cable with many insulated strands. These strands are twisted or braided so each strand shares the same spots. This design helps lower AC resistance from the skin effect and proximity effect. Most litz wire strands are between 28 and 48 AWG. The insulation can be polyurethane, polyvinylformal, or polyimide. The outside layer might use nylon, Nomex®, fiberglass, or plastic. The material depends on where you use the wire.

Tip: Litz wire is not just for radio frequencies. You can use it in many high-frequency circuits, like power supplies and RF transmitters. The twisting of the strands keeps the current flowing evenly, which is important for high-frequency performance.

You see litz wire in more places than ever in 2025. New technology makes devices work at higher frequencies. Litz wire helps these devices stay efficient and cool. You find litz in electric vehicles, wind turbines, and even in 5G networks. The need for litz wire grows because companies want smaller, faster, and more energy-saving products.

Here are some reasons why litz wire matters now:

AI and automation make litz wire better and lower defects.

Smart litz wire with sensors lets you check performance right away.

Eco-friendly materials and recycling make litz wire better for the planet.

New insulation methods help litz wire handle higher voltages and heat.

Litz wire works well with new semiconductors like SiC and GaN, which are used in modern power systems.

| Industry | Why Litz Wire Is Important in 2025 |

|---|---|

| Consumer Electronics | More smart devices need high-frequency, miniaturized litz wire for better performance. |

| Automotive | Electric cars use litz wire to boost motor and powertrain efficiency. |

| Telecommunications | 5G networks rely on litz wire for fast, low-loss data transmission. |

| Aerospace & Defense | Litz wire helps make planes lighter and more efficient, cutting fuel use and emissions. |

You may think litz wire only helps at very high frequencies, but it also works at audio frequencies. Litz wire lowers losses in many types of circuits. You get better performance and less wasted energy.

When you use wires to carry high frequency currents, you face a problem called the skin effect. The skin effect means that alternating current does not flow evenly through the whole wire. Instead, most of the current moves near the surface of the conductor. The deeper you go inside the wire, the less current you find. This happens because the changing magnetic field from the AC creates eddy currents inside the wire. These eddy currents push the main current toward the surface.

You can measure how deep the current goes with something called skin depth. Skin depth is the distance from the surface where the current drops to about 37% of its value at the surface. The formula for skin depth is δ = √(2ρ / μω), where ρ is resistivity, μ is permeability, and ω is angular frequency. As the frequency goes up, the skin depth gets smaller. For example, in copper at 10 MHz, the skin depth is only about 0.066 mm. This means almost all the current flows in a very thin layer on the outside of the wire. When this happens, the wire's resistance increases, and you lose more energy as heat. This is a big problem for devices that use high frequency currents.

You also need to know about the proximity effect. When you put wires close together, the magnetic fields from each wire interact. This makes the current bunch up on the sides of the wires that are closest to each other. The proximity effect gets worse as the frequency increases. It can raise the resistance of the wires by more than 50% at frequencies above 1 MHz. You see this effect in transformers, inductors, and high-frequency circuits. The result is more ac power loss and extra heat.

Note: Both the skin effect and proximity effect make it harder for you to send high frequency currents through regular wires. You get more eddy current losses and higher temperatures, which can damage your devices.

Litz wire gives you a smart way to fight the skin effect and proximity effect. The secret is in how litz is built. Instead of one thick wire, litz wire uses many thin, insulated strands. Each strand is much smaller than the skin depth for the frequencies you use. The strands twist or weave together along the length of the wire. This design helps in several ways:

The twisting and weaving make sure each strand spends time at different spots in the bundle. This means no strand always stays on the outside or inside. The current spreads out more evenly.

The insulation around each strand stops the current from jumping between strands. This keeps the current from piling up on the outside strands.

The arrangement of the strands reduces the proximity effect. The strands do not let the current bunch up on the sides facing other wires.

The design lowers the ac resistance. You get a resistance that is almost the same as the DC resistance, which is what you want for high-frequency circuits.

You see less heat and better efficiency in your devices.

You can see the difference in real tests. When you measure AC resistance versus frequency for litz wire, the resistance stays almost flat up to about 100 kHz. This shows that litz wire keeps the current spread out and stops the skin effect from raising resistance. Solid wires, on the other hand, show a big jump in resistance as frequency goes up. Litz wire can cut AC resistance by up to 70% compared to solid conductors at high frequencies. This means your transformers, motors, and other devices stay cooler and work better.

Dowell's model, based on Maxwell's equations, matches what you see in experiments. Litz wire reduces both skin and proximity effect losses.

Studies show that litz wire's many insulated strands lower eddy current losses at high frequencies.

Time-domain tests prove that litz wire works well in electric motors and generators, where AC losses matter most.

Tip: If you want to get the best performance from your high-frequency circuits, use litz wire. You will see less ac power loss, lower temperatures, and longer-lasting equipment.

| Effect | Problem in Solid Wire | How Litz Wire Helps |

|---|---|---|

| Skin Effect | Current only flows on the surface | Thin strands keep current spread out |

| Proximity Effect | Current bunches near other conductors | Twisted strands balance the current |

| Eddy Current Losses | More heat and wasted energy | Insulation and design reduce losses |

You can trust litz wire to solve the problems caused by high frequency currents. The special construction of litz makes it the top choice for modern electronics, power systems, and any device where efficiency matters.

There are many kinds of litz wire you can pick in 2025. Each kind twists and bundles the strands in a special way. The way you choose changes how well the wire works for you. Look at this table to see the main types and what makes them different:

| Type | Construction Description | Distinguishing Features |

|---|---|---|

| Type 1 | Single film-insulated wire strand twisted, optional outer insulation | Basic twisted insulated strands with optional outer insulation |

| Type 2 | Bundles of Type 1 twisted together, optional outer insulation | Grouping of Type 1 bundles into larger twisted bundles |

| Type 3 | Bundles of Type 2 twisted together, optional outer insulation | Further bundling of Type 2 groups for larger constructions |

| Type 4 | Bundles of Type 2 twisted around a central fiber core, optional outer insulation | Incorporates a fiber core for structural support |

| Type 5 | Insulated bundles of Type 2 twisted around a fiber core, optional outer insulation | Adds insulation to bundles twisted around fiber core |

| Type 6 | Insulated bundles of Type 4 twisted around a fiber core, optional outer insulation | Round geometry, inert fiber core increases outer diameter, improves current carrying at high frequencies |

| Type 7 | Film-insulated wire braided into rectangular profile, optional outer insulation | Rectangular shape formed by braiding film-insulated wires |

| Type 8 | Compacted film-insulated wires/groups twisted and compressed into rectangular profile, outer insulation | Compacted and compressed rectangular profile for space efficiency |

| Type 9 | Coax-style construction with Litz wire core, controlled dielectric insulation, additional braid matching conductor area, optional outer insulation | Specialized coaxial design with transposed bundles and controlled dielectric properties |

You must pick the right type for your frequency range. Higher frequencies need thinner strands to stop the skin effect. If you use thick strands, you get more eddy current losses. Some litz types have fiber cores or special shapes. These help the strands stay close to the surface. This keeps losses low in big transformers and other tough jobs.

Tip: Always check which strand gauge is best for your frequency. For example, at 100 kHz, a 40 AWG strand is a good choice. This helps your litz wire work well in transformers, inductors, and motors.

Litz wire is used in many fields in 2025. Its special build helps lower AC losses and keeps things cool. Here are some of the most common ways people use it:

Transformers and inductors in power supplies

High power transformers for renewable energy

Electric vehicle motors and chargers

Wireless power transmission systems

Medical electronics and sensor wiring

Robotics and automation equipment

Litz wire helps these devices work better. You can use more current at high frequencies without too much heat. Devices get smaller and lighter. You also avoid hot spots and save energy. In communications, litz wire lets data move fast with less signal loss. In green energy, it helps wind turbines and solar inverters work better.

You also find litz wire in aerospace, military, factories, and even food processing. More devices need to work at higher frequencies, so demand grows. You get better power use, smaller products, and longer equipment life.

Note: Litz wire gives you a big advantage when high-frequency currents matter. You get strong, high-quality connections and better results in your projects.

When you choose litz wire, you need to look at several important factors. Each one affects how well your wire will work in your project. Here are the main things you should check:

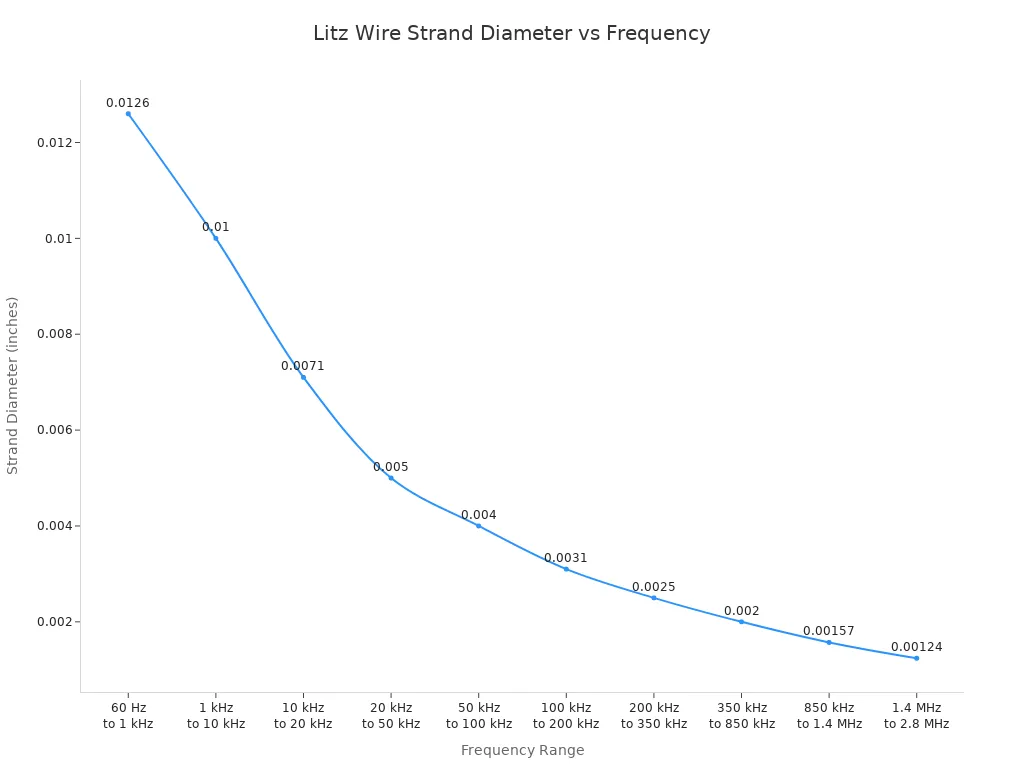

Strand Diameter vs Skin Depth: Pick a strand diameter smaller than one-third of the skin depth at your frequency. For example, at 200 kHz, use a strand about 0.05 mm thick.

Number of Strands: More strands mean better flexibility and less skin effect. High strand counts help carry more current and keep your wire easy to bend.

Wire Construction: The way strands twist or bunch together changes how the wire handles high frequencies. At least three twists per turn length is best.

Packing Factor: This tells you how much copper fills the wire. A higher packing factor means more copper and better performance.

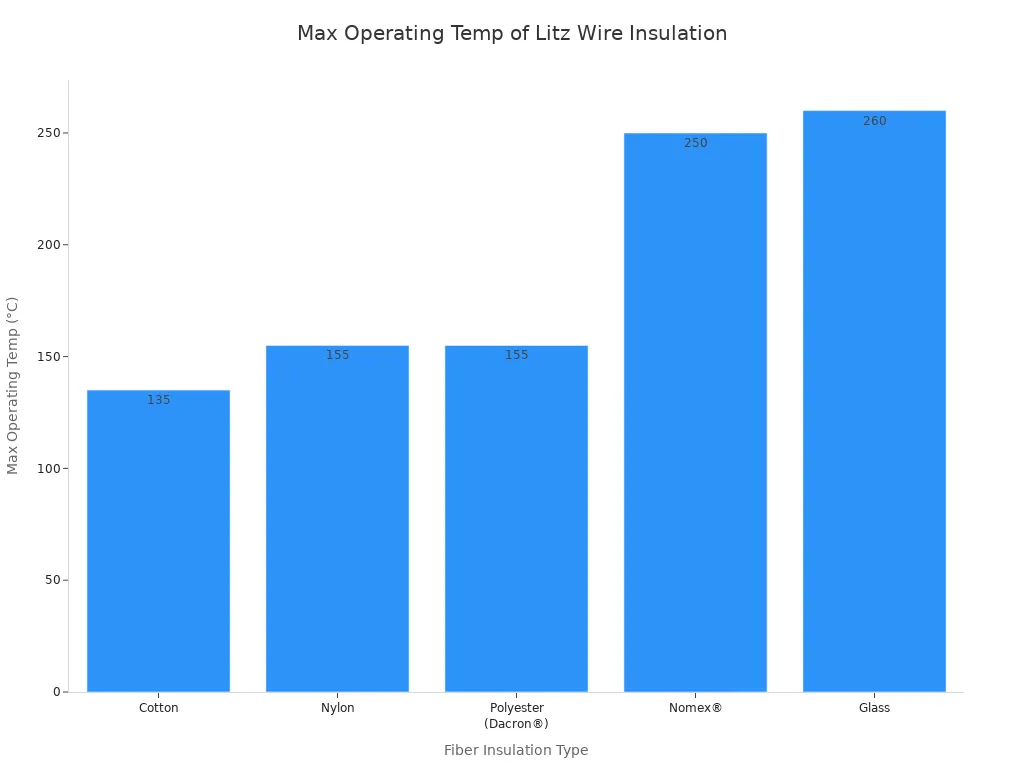

Insulation Type and Thermal Class: Each strand has enamel insulation. Choose a thermal class like F (155°C) or H (180°C) for safety.

Frequency Range: Litz wire works best below 500 kHz. It can work up to 1 MHz, but not much higher.

Served vs Unserved: Served wires have a textile wrap for extra strength. Unserved wires do not.

Certifications: Look for wires that meet IEC 85 or other standards for safety and reliability.

Tip: Always match the strand size and insulation to your frequency and temperature needs. This helps you get the best results when you buy litz wire.

The serve material is the outer wrap that protects your litz wire. Each material has its own strengths. Some are better for high heat, while others are easier to solder. Check this table to compare the most common serve materials:

| Serve Material | Max Operating Temp | Diameter Increase | Solderable | Cost |

|---|---|---|---|---|

| Cotton | ~105°C | Moderate | No | Low |

| Silk | ~110°C | Small | Yes | High |

| Nylon | ~155°C | Small | Yes | Low |

| Polyester | ~155°C | Moderate | Yes | Medium |

| Nomex® | ~204°C | Small/Moderate | No | High |

| PTFE | ~260°C | Large | No | High |

| Fiberglass | ~260°C | Variable | No | High |

Nylon and polyester serve materials give you good protection and are easy to solder. Cotton is cheap but does not handle high heat. Nomex® and PTFE work in very hot places but cost more and are not solderable. Always pick the serve that matches your environment and budget.

In 2025, there are many new changes for Litz wire. Better materials help Litz wire carry electricity and handle heat. Factories now use machines to make Litz wire more quickly. This makes Litz wire work better and cost less. There are also new types, like taped Litz wire. These have stronger insulation and last longer. It is easier to use them, so your projects work better.

New materials help Litz wire work well in transformers and inductors.

Machines in factories make Litz wire faster and cheaper.

Taped Litz wire has stronger insulation and lasts longer.

Companies use greener materials to follow new rules.

These changes let you use Litz wire in more places. You get better results in electric cars, green energy, and high frequency power circuits. You also have fewer problems with heat and wasted energy.

Litz wire will keep growing a lot in the next five years. Electric cars and green energy need more powerful wires. Smaller electronics need tiny, strong wires. More companies want to save energy and stop interference.

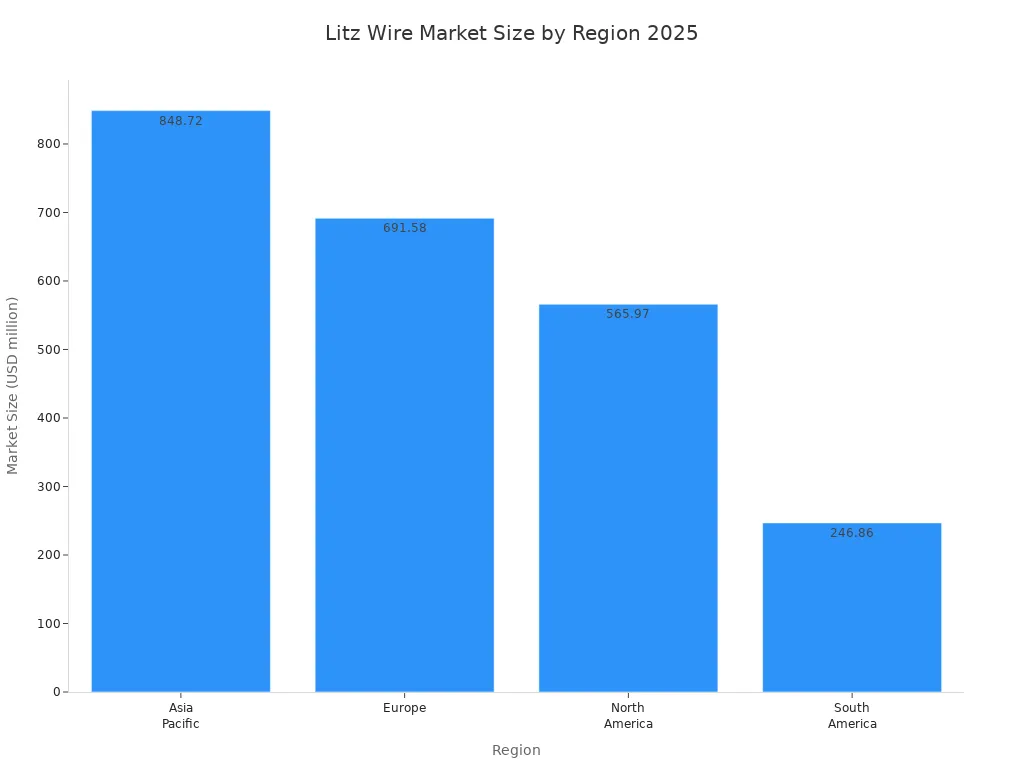

The Litz wire market could be worth $2.8 billion by 2033.

Asia-Pacific, especially China, makes and uses the most Litz wire.

Car and medical companies use more Litz wire in vehicles and devices.

Wireless charging is more popular, and Litz wire helps it work well.

There are some problems too. Making Litz wire costs a lot, and copper or silver prices can change. Rules and standards keep changing, so you must learn new things to stay safe and legal. Getting supplies and other materials can be hard, and there is more competition.

Note: Rules decide how you use Litz wire. They help customers trust your products but can make it tough for new companies. You need to keep learning and follow new rules to stay ahead.

You now know why Litz wire matters in 2025. When you choose Litz wire, you must match the strand gauge to your frequency range for the best results.

Litz wire cuts AC losses and boosts efficiency in high-frequency circuits.

You need to consider frequency, current, insulation, and winding type.

Preformed Litz wire helps make devices smaller and more efficient.

If you want more help, you can check resources from New England Wire Technologies or YIDA Wire Industry Co., Ltd. Their guides and experts can answer your questions about Litz wire design and selection.

You need to remove the enamel insulation from each strand before soldering. Use a solder pot, chemical stripper, or mechanical scraper. After cleaning the strands, twist them together and apply solder. This gives you a strong, reliable connection.

Litz wire works best below 500 kHz. You can use it up to 1 MHz, but performance drops at higher frequencies. For very high frequencies, choose thinner strands. Always match the strand size to your application.

You can use Litz wire outdoors if you pick the right insulation and serve material. Choose weather-resistant options like PTFE or Nomex®. These materials protect the wire from moisture, sunlight, and temperature changes.

Litz wire costs more because it uses many thin, insulated strands. The twisting and insulation process takes more time and special machines. You pay more up front, but you save energy and get better performance in high-frequency circuits.