English ![]()

Tel: +86-13732621090

Email:yewu001@yushengdz.com

4F, No.68, Huian Road, Xukou Town, Wuzhong District, Suzhou, Jiangsu, China, 215105

Views: 0 Author: Site Editor Publish Time: 2025-07-28 Origin: Site

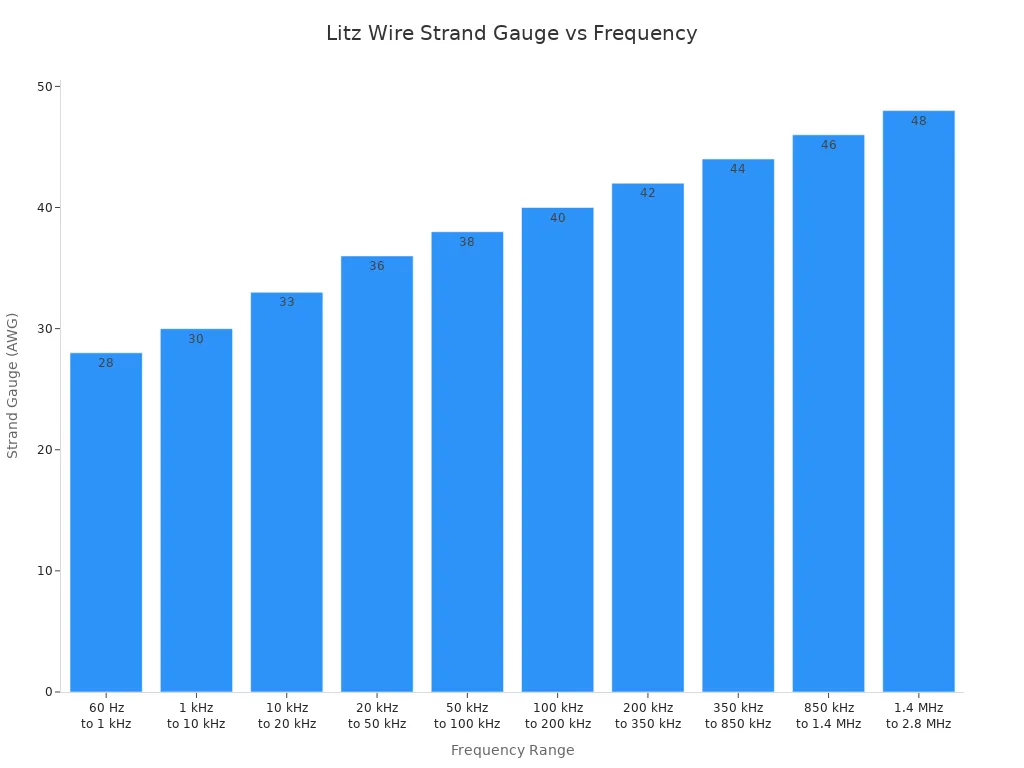

Litz wire has many thin strands. Each strand is covered with its own insulation. The strands are twisted or grouped together. This design helps lower AC losses in high-frequency uses. Each strand carries some of the current. The twisting can be done in one group or in several groups. Common insulation types are polyurethane, nylon, and polyester. The table below shows which strand size fits different frequency ranges:

| Frequency Range | Recommended Strand Gauge (AWG) |

|---|---|

| 60 Hz to 1 kHz | 28 |

| 1 kHz to 10 kHz | 30 |

| 10 kHz to 20 kHz | 33 |

| 20 kHz to 50 kHz | 36 |

| 50 kHz to 100 kHz | 38 |

| 100 kHz to 200 kHz | 40 |

| 200 kHz to 350 kHz | 42 |

| 350 kHz to 850 kHz | 44 |

| 850 kHz to 1.4 MHz | 46 |

| 1.4 MHz to 2.8 MHz | 48 |

Litz wire is special because it fixes the skin effect. The skin effect makes current flow near the wire’s surface at high frequencies. Litz wire helps make things work better and lose less power. Engineers use litz wire in many things. Some examples are transformers, wireless charging, medical devices, and motors.

Litz wire has many thin, insulated strands twisted together. This helps stop energy loss when the frequency is high. This special design solves the skin effect. The skin effect makes current flow only on the outside of the wire. This wastes power. Litz wire makes things work better by lowering resistance and heat. It helps devices like transformers and wireless chargers work well. Litz wire is flexible and has strong insulation. This makes it tough and easy to use in small spaces and hard places. Engineers use Litz wire in many areas. These include medical devices, radio equipment, and electric car charging. It helps save energy and makes things work better.

Litz wire stands out because of its unique build. It uses many thin strands of wire. Each strand has its own enamel insulation. These strands twist or weave together in special patterns. This design helps the wire carry high-frequency currents with less loss.

Each strand in litz wire is much thinner than those in regular wires.

The strands are bundled in complex braids or layers.

Enamel insulation covers every strand. This prevents short circuits and protects against oxidation.

Litz wire often has extra layers, like silk or nylon, for more strength and isolation.

The twisting and weaving patterns make sure each strand shares the current equally.

Litz wire can be made for different needs. The number of strands, their size, and the type of insulation can all change. Some litz wires use special patterns, called Types 1 to 6, to match certain uses. The enamel insulation usually meets high thermal standards, so the wire can handle heat. Extra serving layers add mechanical protection and help the wire last longer.

Tip: Litz wire’s flexibility makes it easy to use in tight spaces or winding coils.

Litz wire differs from solid or standard stranded wire in many ways. Solid wire has one thick core. Standard stranded wire has several wires twisted together, but the strands do not have their own insulation. Litz wire, on the other hand, uses many insulated strands. This design gives it special electrical and physical properties.

Litz wire reduces skin effect and proximity effect. These problems cause current to flow only on the surface at high frequencies.

The insulation on each strand keeps the current spread out. This lowers resistance and heat loss.

Litz wire stays flexible, even in large sizes. Solid wire can break if bent too much.

The special twisting patterns help each strand take turns at different positions. This keeps the current balanced.

Litz wire works well for radio frequencies and high-frequency power supplies.

Litz wire’s construction lets it perform better in high-frequency circuits. It keeps signal quality high and reduces energy loss. The insulation and weaving also make litz wire more durable and easier to handle than solid wire. Users often choose litz for sensitive electronics, like audio cables or wireless charging coils, because it keeps losses low and performance high.

The skin effect happens when AC moves through a wire. At low frequencies, the current spreads out inside the wire. When the frequency gets higher, the current moves to the wire’s surface. This happens because eddy currents form inside the wire. These eddy currents push the main current outward. Most of the current then travels in a thin layer near the surface. This thin layer is called the skin depth. For copper, the skin depth is about 8.5 millimeters at 60 Hz. At 1 GHz, it can shrink to just 2 microns. When the skin depth gets smaller, the inside of the wire carries almost no current. This makes the wire’s resistance go up and wastes more energy. The skin effect does not happen with DC. DC flows evenly through the whole wire. The proximity effect also shows up at high frequencies. When wires are close together, their magnetic fields interact. This pushes current into even smaller spaces. That makes resistance and energy loss even worse.

Note: The skin effect and proximity effect both make it harder for wires to carry high frequency currents without losing energy.

Litz wire fixes the skin effect by using many thin, insulated strands twisted together. Each strand is so small that high frequency currents can flow through all of it. The insulation keeps the current from jumping between strands. The twisting pattern, called transposition, lets each strand move from the inside to the outside of the bundle. This helps spread the current evenly and lowers both skin effect and proximity effect. Studies show that litz wire has much lower AC resistance than solid wire of the same size. The special twisting and insulation also cut down on eddy current losses. In high frequency power circuits, litz wire keeps energy loss low and helps things work better. Engineers use litz in transformers, inductors, and other devices that need high frequency currents. The special way litz wire is made helps reduce losses and keeps devices working well.

Litz wire helps electronics work better at high frequencies. It has many thin, insulated strands that carry current together. This design spreads the current across the whole wire. Litz wire stops skin effect and proximity effect. These problems can cause more resistance and waste energy. Devices like transformers and inductors use litz wire for better results.

Litz wire uses many thin strands to lower AC resistance.

It stops hot spots and keeps things cooler.

Magnetic parts can be smaller and lighter because litz wire needs less metal.

Litz wire lets devices work well at very high frequencies.

Litz wire helps engineers make smaller and better power supplies. These changes save energy and cut down on heat in electronics.

Litz wire is great at lowering AC power loss. Its special build cuts down skin effect and proximity effect. This means less energy turns into heat. More power goes to the device.

Litz wire spreads current out, so resistance and power loss are lower.

It cuts down on eddy current losses, which waste energy in solid wires.

Litz wire stops hot spots, so devices are safer and last longer.

Lower losses let devices run longer without getting too hot.

Litz wire also helps the planet. Polyurethane, polyester, and polyimide insulations last a long time. Some makers use recycled copper and safe insulation to help the earth. Green ways of making litz wire and rules like RoHS and REACH protect nature. Litz wire saves energy, which helps the world use less power.

Litz wire bends easily, so it works in many places. The thin, insulated strands twist and bend without breaking. This helps engineers wind coils tight or fit wires in small spots.

Polyurethane insulation makes litz wire tough and hard to scratch.

Polyester insulation gives strength and keeps out chemicals.

Polyimide insulation lets litz wire handle high heat, good for planes and medical tools.

Special plastics and mixes let makers change litz wire for different jobs.

| Failure Mode / Limitation | Description / Cause |

|---|---|

| Increased Eddy Current Losses at Cryogenic Temperatures | At very low temperatures, litz wire can lose efficiency if not designed carefully. |

| Skin and Proximity Losses | High frequencies and low resistivity can still cause losses if strand size and twisting are not optimal. |

| Mechanical Constraints During Winding | Complex winding can stress the wire, making manufacturing harder. |

| Sensitivity to External Magnetic Fields | Strong magnetic fields can increase losses, especially at high frequencies. |

| Lack of Comprehensive Design Data | Limited data on best strand sizes and patterns can make design challenging. |

Litz wire’s bendy build and special insulation help it last longer. It also works better in tough places. These good points make litz wire a top pick for engineers who need strong, high-frequency wires.

Litz wire is used in many modern electronics. Its special structure makes it good for high-frequency jobs. It also helps devices work with less wasted energy. Below are some main ways litz wire is used in different fields.

Wireless charging systems need litz wire to work well. The wire has many insulated strands. These strands help stop heat and save energy. In drone charging pads, litz wire coils make charging faster and more stable. They also lower energy loss. Electric vehicle charging stations use litz wire in their coils too. The wire handles high currents and frequencies. This keeps the system cool and working well. Studies show litz wire keeps transfer efficiency high. This is true even if the coils are not lined up perfectly. Because of this, wireless charging is more reliable for phones, cars, and robots.

Note: Litz wire lowers skin and proximity effects. This is very important for wireless charging.

Transformers and inductors often use litz wire. In big transformers, litz wire lowers AC resistance. This helps the device work better. Electronics, data centers, and green energy systems use litz wire to save energy. It also helps cut down on heat. Inductors in cars, phones, and factories use litz wire too. It helps them filter signals and store energy with less loss. Car makers use litz wire in transformers and inductors for electric vehicles. They also use it in driver-assistance systems. This helps with power changes and heat control.

Transformers in power supplies and converters use litz wire for better results.

Inductors in smart gadgets and 5G gear use litz wire for good signal handling.

Medical and RF devices need wiring that works well and is safe. Litz wire helps by lowering coil resistance and heat. In medical wireless power systems, like MRI machines and hearing aids, litz wire keeps coils cool. This stops tissue damage. The wire’s build makes sure current flows evenly. This is important for safety and good performance. RF equipment, like radar and radios, uses litz wire to keep signals clear at high frequencies. The healthcare field likes silk wrap litz wire. It is strong and conducts well. This helps devices last longer and work better.

Litz wire helps medical and RF devices work safely and well, even at high frequencies.

Litz wire comes in many types. Each type fits different needs in electronics. The table below shows the main categories and features:

| Category | Details |

|---|---|

| Litz Wire Types | Types 1–9: Each has a special build and use. Types 1 & 2 are for small, high Q circuits. Types 3–6 are for bigger power jobs and radio transmitters. Type 7 is braided. Type 8 is flat or rectangular. Type 9 blocks interference. |

| Strand Count | Thin wires from 28 to 48 AWG. The right size depends on the frequency. Thinner strands work better at higher frequencies. |

| Insulation Types | Each strand has its own insulation. Choices include polyvinylformal, polyurethane, nylon, polyimide, and solderable polyester. The outside can have nylon, cotton, Nomex®, fiberglass, or ceramic. |

| Geometry | Most litz wire starts round. Some types can be shaped into squares or rectangles for tight spaces. |

| Preformed Wire | Types 2 and 8 can be twisted or shaped for special uses. |

| Application Notes | The strand size should match the skin depth at the working frequency. Some coatings make soldering easier. |

Polyesterimide film insulation stands out for its strong heat and chemical resistance. This makes litz wire last longer in tough places.

Selecting the best litz wire for a project takes careful thought. Here are some practical tips:

Check the frequency range. Pick the right strand size and number for your device.

Look at how much current and heat the wire will handle. Make sure it can take the load.

Think about how the wire will be wound. The way you arrange turns and layers affects losses.

Use software tools to predict losses and test designs. Many companies offer free tools for this.

Choose insulation that matches your environment. Some materials resist heat, chemicals, or moisture better.

Make sure the wire fits your space. Flat or shaped wires help in tight spots.

Balance cost and reliability. Good litz wire can prevent future problems.

Insulation on each strand keeps the wire safe and strong. It also helps the wire work well in hot or harsh places.

For special uses, like electric cars or medical devices, talk to trusted suppliers before you buy litz wire.

Tip: Always match the strand size to the frequency and current needs. This helps your device run better and last longer.

Litz wire helps electronics work better and stay cool. Its special design lowers energy loss in devices. Studies and tests show it reduces skin and proximity effect losses. This makes litz wire a top pick for high-frequency jobs. Engineers use it in things like transformers and wireless charging. It is also used in medical devices. If you want to learn more, check the table below for trusted sources and research articles.

| Reference | Authors | Publication | Year | Focus |

|---|---|---|---|---|

| Fast numerical power loss calculation for high-frequency litz wires | Ehrlich S. et al. | IEEE Transactions on Power Electronics | 2021 | Numerical power loss calculation |

| An analytical loss model of litz-wire windings for transformers excited by converters | Li H. et al. | IEEE Transactions on Magnetics | 2019 | Analytical loss modeling |

| Realistic litz wire characterization using fast numerical simulations | Zhang R.Y. et al. | IEEE Applied Power Electronics Conference (APEC) | 2014 | Numerical simulations |

| 3D Finite Element Simulation of Litz Wires with Multilevel Bundle Structure | Plumed E. et al. | IECON Conference | 2018 | Finite element simulation |

| Eddy current analysis of litz wire using homogenization-based FEM | Hiruma S., Otomo Y., Igarashi H. | IEEE Transactions on Magnetics | 2018 | Eddy current analysis |

| Loss computation method for litz cables with emphasis on bundle-level skin effect | Gyimóthy S. et al. | IEEE Transactions on Magnetics | 2019 | Loss computation |

| Calculation of power losses in litz wire systems by coupling FEM and PEEC method | Rosskopf A. et al. | IEEE Transactions on Power Electronics | 2016 | Power loss calculation methods |

| Litz Type TEX-ELZ product information | Furukawa Electric Co., Ltd. | Industrial source | N/A | Product and technical data |

| COMSOL AC/DC Module Users Guide | COMSOL | Software documentation | N/A | Simulation tool guide |

Litz wire has many thin, insulated strands. Each strand carries some of the current. This helps stop energy loss from the skin effect. Regular wire cannot do this at high frequencies.

Some Litz wires have coatings that make soldering simple. Others need you to remove the insulation first. Always check what kind of wire you have before you start.

Engineers use Litz wire in transformers and wireless charging coils. It is also used in medical devices and radio equipment. These devices need to work well at high frequencies and save energy.

Litz wire works best for AC, especially at high frequencies. It does not help with DC because the skin effect does not happen with direct current.

Always pick the strand size and insulation that fit your device’s frequency and where it will be used. Use tables or ask a supplier for help. The right choice makes your device safer and work better.