English ![]()

Tel: +86-13732621090

Email:yewu001@yushengdz.com

4F, No.68, Huian Road, Xukou Town, Wuzhong District, Suzhou, Jiangsu, China, 215105

Views: 0 Author: Site Editor Publish Time: 2025-07-26 Origin: Site

Litz wire is made of many thin, insulated strands. These strands are woven or twisted together. Engineers use litz wire in high-frequency AC circuits. It helps lower energy loss from the skin effect. The special design of litz wire lets current flow more evenly. This gives big improvements in efficiency:

At high frequencies, regular wire can have AC resistance 20 times higher than litz wire of the same size.

Litz wire can lower AC losses by 80% to 90% or even more compared to regular wire.

These features make litz wire a great choice for tough electrical jobs.

Litz wire has many thin, insulated strands twisted together. This helps lower energy loss in high-frequency AC circuits.

Its special design keeps current flow even and lowers resistance from the skin effect. This can make it up to 90% more efficient.

Picking the right strand size and number depends on frequency and current. This helps keep energy loss low and performance high.

Litz wire is used in transformers, inductors, motors, and wireless charging. It helps these things work better and stay cooler.

Good insulation and strong build make litz wire flexible and tough. It works well for hard electrical jobs in many industries.

The word litz comes from a German word. It means braided or stranded wire. This shows how litz wire is made. Litz wire has many thin strands of copper or other metals. Each strand has its own insulation. The strands are twisted or woven together in a special way. This pattern makes each strand move to different spots in the wire. The design helps balance the magnetic fields around each strand. It also lowers unwanted electrical losses.

Litz wire is different from regular wire because of its build. In a solid wire, current flows near the surface at high frequencies. This is called the skin effect. It raises resistance and wastes energy. Litz wire fixes this by using many insulated strands. Each strand carries some of the current. This lets the wire handle high-frequency signals better.

Note: Litz wire is not just a bunch of wires. The careful twisting and insulation make it perfect for special electrical jobs.

Litz wire has many features that make it special:

Litz wire has lots of thin, insulated strands. This stops short circuits between strands.

The strands are twisted or woven in tricky patterns. These patterns can have many layers or steps.

Each strand moves to different spots inside the wire. This helps balance the magnetic fields.

The design lets current spread out evenly in all strands. This cuts down resistance and energy loss from the skin effect and proximity effect.

The strands are very thin. Some have special coatings like enamel or silver to work better.

Litz wire’s braided or woven build makes it different from solid or normal stranded wire. This helps it work great in high-frequency and radio frequency circuits.

The wire is flexible and has a lot of copper. This makes it easy to wind into coils for transformers, inductors, and other devices.

Makers can change the number of strands, strand size, and twist pattern. These changes help litz wire work in many frequency ranges.

Special insulation like silk, nylon, or strong plastics makes it tougher and better at handling electricity.

Litz wire can be round or rectangular to fit different designs.

Litz wire’s build helps with high-frequency problems. Thin strands, good insulation, and careful twisting all help lower losses from the skin effect and proximity effect. This makes litz wire work better than solid or simple stranded wire in tough electrical jobs.

The skin effect happens when AC flows in a wire. At low frequencies, current fills the whole wire. When the frequency goes up, current moves to the wire’s surface. This happens because eddy currents form inside the wire. These eddy currents push the main current to the outside. The center of the wire carries less current. The surface carries more current.

At 60 Hz, the skin effect is not a big problem. Most of the wire still works well. When the frequency gets higher, the skin effect gets stronger. For example, in copper wire, the skin effect matters above 20 kHz. At these high frequencies, only a thin layer at the surface carries most of the current. The rest of the wire does not help much. This makes the wire’s resistance go up and causes more heat.

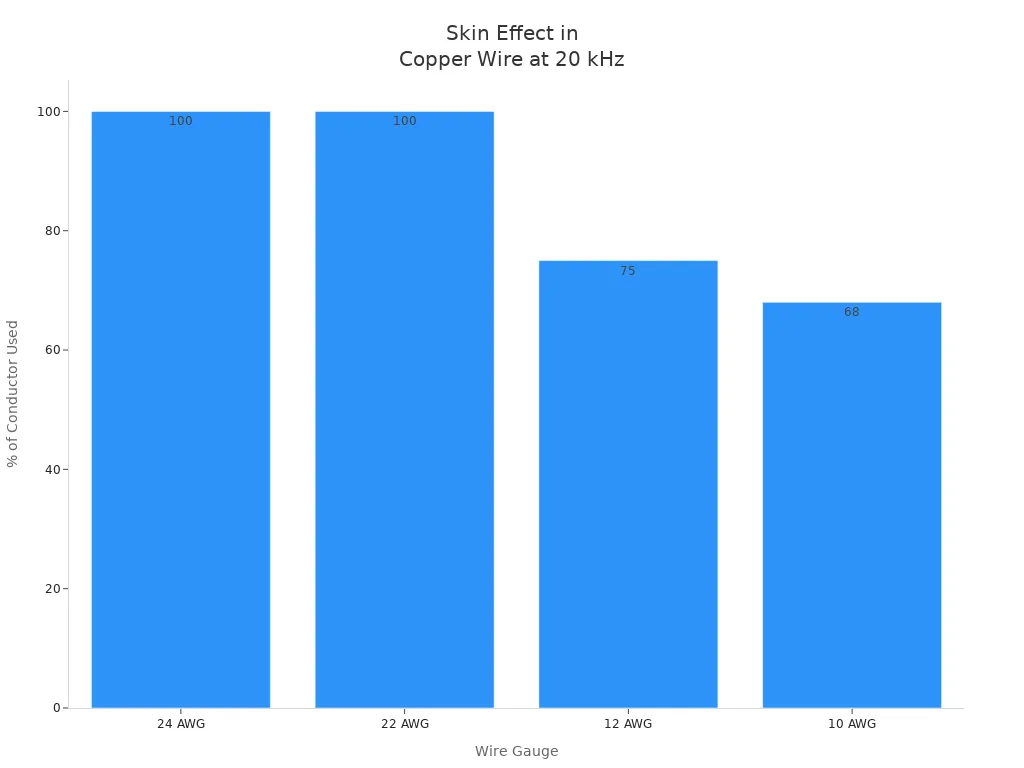

The table below shows how much of a copper wire’s area carries current at 20 kHz:

| Wire Gauge | Diameter (inches) | Approximate % of Conductor Used at 20 kHz |

|---|---|---|

| 24 AWG | 0.024 | 100% |

| 22 AWG | 0.031 | 100% |

| 12 AWG | 0.093 | 75% |

| 10 AWG | 0.115 | 68% |

This chart shows that thin wires use all their area at 20 kHz. Thick wires lose a lot of their useful area. The skin effect makes resistance higher and creates more heat. It also lowers efficiency when using high frequency currents. Engineers must think about this effect when they design circuits for radio, power electronics, and other high-frequency uses.

Tip: The skin effect also raises ac power loss and can cause signal problems in high-frequency circuits.

Litz wire fixes the problems from the skin effect. Litz wire has many thin, insulated strands twisted together. Each strand is about the same size as the skin depth for the needed frequency. This lets high frequency currents use almost the whole strand. The insulation keeps each strand apart, so current does not jump between them.

The twisting pattern moves each strand to different spots in the bundle. This helps balance the magnetic fields around each strand. It also spreads the current evenly in all the strands. Litz wire lowers ac resistance and keeps heat down. The wire can carry more current with less energy loss.

Engineers use litz wire in transformers, inductors, and other devices for high frequency currents. Tests and computer models show litz wire can cut ac resistance by up to 30% compared to solid wire. Advanced simulation tools, like ANSYS MAXWELL and FEMM, confirm these results. Both experiments and models agree that litz wire lowers ac losses, especially in complex shapes like planar transformers.

The main features that help litz wire work include:

Many individually insulated strands twisted together.

Each strand sized to match the skin depth at the operating frequency.

Twisting ensures uniform current distribution.

Insulation prevents short circuits between strands.

The design reduces eddy current losses and keeps ac to dc resistance ratios low.

Note: Litz wire’s special construction makes it the best choice for reducing skin effect and eddy current losses in high-frequency circuits.

Manufacturers pick certain materials to make litz wire work well at high frequencies. Copper is the most popular metal for the strands. Copper is good at carrying electricity and heat. This helps stop eddy current losses and the skin effect when the frequency is high. Using many thin copper strands gives more surface area. This lets the current spread out better and lowers AC resistance. More surface area also helps get rid of heat faster. This makes inductors and transformers last longer and work better. Lower AC resistance from copper strands means better results and a higher quality factor in high-frequency circuits.

Copper strands help stop eddy current losses and the skin effect.

Having many strands gives more area for current to flow.

Copper helps get rid of heat and makes the wire last longer.

How the strands are put together in litz wire is very important. The number of strands, their size, and how they twist all matter. These things change how well the wire works with high-frequency currents. Twisting the strands the right way lets current flow evenly in all strands. This cuts down losses from the proximity effect and circulating currents. If the twist or pitch is wrong, resistance and losses can go up fast. The way the strands are arranged also changes how bendy or stiff the wire is. Bandaging and bonding make the wire stronger. Random strand placement lets the wire bend and stretch without breaking. These choices help litz wire work in many tough jobs.

Litz wire can be round or rectangular. Some types use nylon or silk wraps to make them stronger and harder to wear out.

Each strand in litz wire has its own insulation. This keeps the strands from touching and causing short circuits. It also helps the wire handle higher voltages. Some common insulation types are formvar, polythermaleze, and soldereze. Formvar and polythermaleze are tough and can take high heat, but they are hard to remove when building things. Soldereze melts when you solder, so it is easier to use, but it may not last as long. Some wires have two or more layers of insulation. This makes them harder to scratch and lets them handle more voltage. Nylon coatings make the wire even tougher, like strong cable ties. The insulation you pick changes how bendy, tough, and strong the wire is. Engineers choose the best insulation for each job.

Litz wire works well up to about 1 MHz. At higher frequencies, the skin depth gets smaller than the strand size. This makes the wire less efficient. Keeping the strand size close to the skin depth helps the wire work better.

Engineers use different types of litz wire. Each type is built in a special way. This helps them work well in transformers and other high-frequency circuits. The table below lists the main types, how they are made, and where they work best:

| Litz Wire Type | Construction Description | Typical Applications |

|---|---|---|

| Type 1 | Single film-insulated strands twisted together; may have extra outer insulation. | General high-frequency windings needing lower AC losses. |

| Type 2 | Bundles of Type 1 strands twisted together; can include a fiber core. | High-frequency windings with better flexibility and insulation. |

| Type 4 | Insulated bundles twisted around a fiber core; may have outer insulation. | Uses needing more insulation and mechanical strength. |

| Type 5 | Bundles of Type 2 litz twisted around a fiber core; optional outer insulation. | Tuning circuits for high power transformers and radio transmitters. |

| Type 6 | Bundles of Type 5 wire with nylon serving and fiber core; optional insulation. | Tuning circuits for high power transformers. |

| Type 7 | Braided film-insulated wire in a rectangular shape; optional insulation. | High-frequency grounding and high-frequency inductors. |

| Type 8 | Single insulated strands twisted and compressed into a rectangular shape; copper density 60-75%. | Motors, generators, transformers, and inverters where space and copper density matter. |

| Type 9 | Coax-style with a core of litz bundles, special insulation, and extra braid. | Special uses needing controlled dielectric properties. |

Each litz type gives a mix of flexibility, insulation, and copper amount. Engineers pick the best type for their transformer or inductor.

Litz wire is important in many electronics today. It helps lower AC losses and makes circuits work better at high frequencies. The table below shows where litz wire is used and what it helps with:

| Application | Performance Benefits | Typical Use Cases |

|---|---|---|

| Transformers | Cuts losses, improves performance in switch-mode power supplies and resonant converters. | Consumer electronics, data centers, renewable energy |

| Inductors | Lowers core and copper losses, keeps high Q-factors, stable across wide frequencies. | Automotive electronics, telecom, industrial automation |

| Motors | Reduces eddy current losses, raises efficiency. | Brushless DC and AC synchronous motors in EVs, robotics, medical devices |

| Wireless Charging | Enables efficient energy transfer, lowers heat, reduces EMI. | Consumer electronics, automotive, industrial wireless power |

| Other Uses | Offers strong electromagnetic properties and reliability. | Medical imaging, aerospace, high-end audio systems |

Litz wire is great for transformers and high-frequency inductors. It keeps AC resistance low. For example, at 100 kHz, a Type 2 litz wire with 450 strands has AC resistance almost the same as DC resistance. A solid wire at the same frequency has much higher AC resistance. This means litz wire works better in high-frequency power circuits.

But litz wire is not always the best choice. In jobs with very high current or very high frequency, flat copper wire or copper foil can be better. Flat copper wire handles heat well and is strong. It also costs less and has lower RF resistance in big transformers or lightning grounds. Litz wire, with many strands, can have higher resistance if the strands lose contact or get tarnished. Engineers often use flat copper for high-current jobs where strength and heat control are most important.

Picking the right litz wire means looking at strand size, how many strands there are, and how much current goes through it. Engineers use skin depth at the working frequency to pick the biggest strand size. Each strand should be less than one-third of the skin depth for best results. When the frequency goes up, the strand size must get smaller to keep AC losses low. The table below shows some important sizing rules:

| Parameter | Guideline/Value | Explanation |

|---|---|---|

| Strand Diameter | < 1/3 skin depth | Smaller strands help stop skin and proximity effects. For example, at 200 kHz, δ = 0.148 mm, so dstrand ≈ 0.050 mm |

| Strand Diameter vs Freq. | Decreases as frequency increases | Higher frequencies need thinner strands |

| Current Density | 2-3 A/mm² (no cooling), up to 15 A/mm² (cooled) | This keeps the wire from getting too hot |

| Number of Strands | Based on total current and strand size | More strands let the wire carry more current |

| Packing Factor | 1.25–1.28 depending on strand count | This changes the wire’s size and how well it works |

Getting the right balance between strand size and number of strands helps the wire work well and not cost too much. Thinner strands lower AC losses but make the wire harder to build.

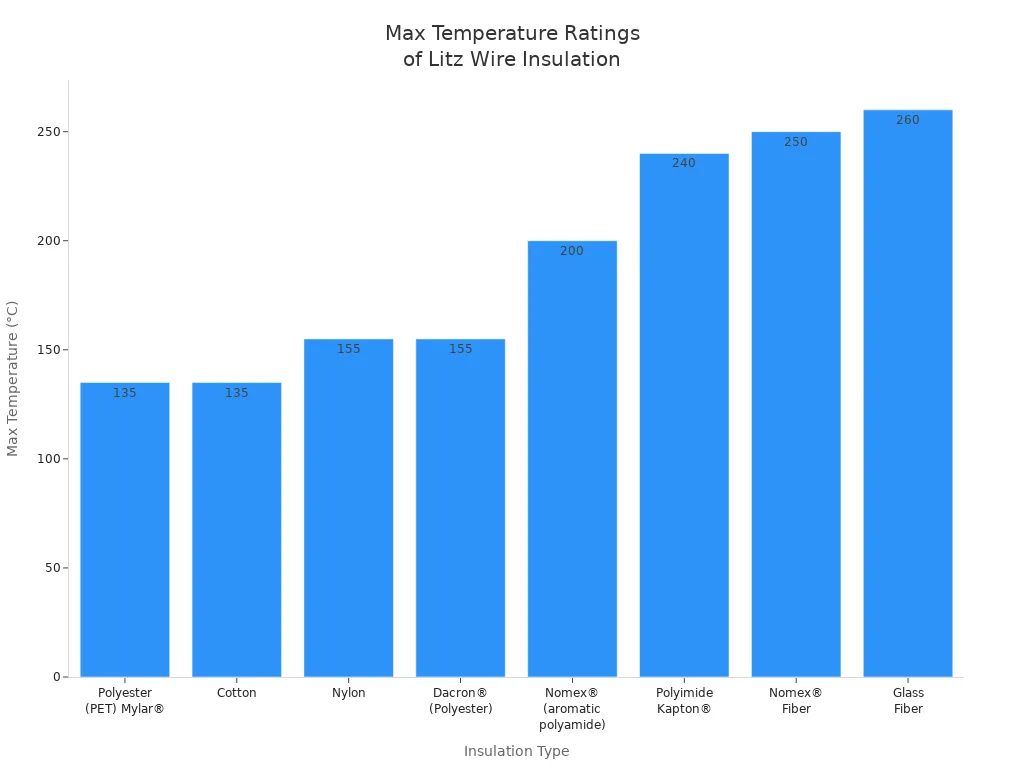

The insulation on litz wire decides how hot it can get and where it can be used. Factories often need insulation that can take high heat. The table below lists some common insulation types and their temperature limits:

| Insulation Material | Max Temperature (°C) | Max Temperature (°F) | Key Characteristics |

|---|---|---|---|

| ETFE | 155 | 311 | Good against chemicals, bends easily |

| FEP | 180 | 356 | Handles heat well, slippery surface |

| PFA | 200 | 392 | Great against heat and chemicals |

| Polyester (PET) Mylar® | 135 | 275 | Strong against electricity, tough coating |

| Nomex® | 200–220 | 392–428 | Bends easily, tough, handles heat |

| Polyimide Kapton® | 240–400 | 464–752 | Very strong against electricity, fire safe |

| Nylon | 155 | 311 | Tough, easy to solder |

| Glass Fiber | 260 | 500 | Handles high heat, cannot be soldered |

The insulation you pick, like polyurethane or polyimide, changes the wire’s heat rating. Polyimide enamel can take more heat than polyurethane. Serve materials like Nomex® or PTFE let the wire work in even hotter places, so litz wire can be used in tough jobs.

How bendy litz wire is matters when you need to wind it tightly or move it a lot. Many things change how flexible litz wire is:

Textile serves, like nylon or fiberglass, protect the wire but make it less bendy by holding the strands tight.

Tight fibers stop the strands from flattening when bent, which can limit how many times you can wrap the wire.

The kind and number of serve layers change the wire’s thickness and how much it can bend.

Makers try to make litz wire as bendy as possible but still strong.

If you want to solder litz wire, think about the insulation and serve. Some insulation melts when soldered, making it easier to connect, but others need to be taken off by hand.

Making litz wire is hard and needs special machines and skilled workers, which makes it cost more, especially for wires that carry a lot of current. Problems like broken strands or damaged insulation can also raise the price. Even with these problems, litz wire is still very important for high-frequency jobs where saving energy and being reliable are key.

Engineers get many good results when they pick the right wire for high-frequency electronics. The special way litz wire is made, with many insulated strands, helps cut down power loss. It also makes devices work better and keeps them cooler. Choosing the right strand size, insulation, and making sure it meets safety rules helps the wire work safely and last longer in cars, medical tools, and airplanes. Knowing about these things lets engineers build better products that last longer for today’s technology.

Litz wire has many thin, insulated strands twisted together. This helps current move evenly at high frequencies. Regular wire cannot do this well. Litz wire lowers energy loss from the skin effect. It works better in high-frequency circuits.

Litz wire does not help with DC circuits. The skin effect only matters for AC at high frequencies. For DC or low-frequency AC, solid or stranded wire works fine and costs less.

Engineers pick litz wire by looking at frequency, current, and skin depth. They match the strand size to the skin depth for the job. The number of strands depends on how much current is needed. Good sizing keeps resistance low and makes the wire efficient.

Many electrical suppliers and special wire makers sell litz wire. Online stores have many choices too. Buyers should check the specs to make sure the wire fits their needs before buying.

Litz wire bends well because it uses fine strands. Some types have textile serves for extra strength. These can make the wire a bit less bendy. Most litz wire types still work for tight winding in transformers and inductors.