English ![]()

Tel: +86-13732621090

Email:yewu001@yushengdz.com

4F, No.68, Huian Road, Xukou Town, Wuzhong District, Suzhou, Jiangsu, China, 215105

Views: 0 Author: Site Editor Publish Time: 2025-07-25 Origin: Site

Litz wire is made of many thin, insulated strands. These strands are twisted or bundled together. This special design lets each strand carry some of the current. It helps lower losses from the skin effect and proximity effect. Litz wire is important in electronics. It lets current flow more evenly. This makes it useful for high-frequency AC circuits. Engineers use litz wire in many places where efficiency is important. Some examples are transformers and radio frequency equipment.

Litz wire can make things work up to 100% better than regular magnet wire. This is because its design splits the current between many strands.

Litz wire has many thin, insulated strands twisted together. This helps stop energy loss when the frequency is high. Its special design lets current flow evenly. This lowers resistance and keeps devices cooler. It also makes them work better. Litz wire is used in electric cars, transformers, and power electronics. It is also used in radio frequency equipment for better performance. Picking the right strand size and insulation is important. This keeps things safe and strong. It also gives the best results. Litz wire costs more and needs special care. But it makes high-frequency circuits work much better.

Litz wire is a special kind of electrical wire. It has many thin wires inside, and each one has its own insulation. The wires are twisted or braided in a certain way. This helps the wire carry AC better, especially at high frequencies. Each strand helps carry the current. This design stops energy loss that happens in normal wires with high-frequency signals. Litz wire is used in many electronics where saving energy is important.

The word "litz" comes from German. In German, "litz" means "woven wire." This matches how litz wire is made. Workers twist or braid the insulated wires together. This makes a woven pattern. The weaving helps the wire work better in circuits. The German word shows how the wire’s design and job are linked. The woven shape lets current flow better and lowers resistance. Engineers picked the name "litz" because it fits how the wire looks and works.

Litz wire has many good points for electrical systems. Its special design is the main reason. Using many insulated wires cuts down on energy loss from the skin effect and proximity effect. These problems waste energy in normal wires, especially at high frequencies. Litz wire helps devices run better and stay cooler.

Studies show litz wire also gets stronger with textile serves. A textile serve is a layer wrapped around the wire. This layer keeps the insulation safe when the wire is cut or bent. The serve protects against sharp edges and pressure. But, adding a serve can make the wire less bendy because it holds the wires tight.

Litz wire is being used more now. More electric cars, smart gadgets, and 5G networks need litz wire for better results. Car makers use litz wire to make motors and transformers work better. Electronics companies pick litz wire for its high-frequency and low-loss features. Asia Pacific uses the most litz wire, but North America and Europe are growing too. Aerospace companies use litz wire for light and strong needs.

Litz wire is great at saving energy, stopping damage, and helping new technology. These reasons make it a top pick in many fields.

Litz wire is special because of how it is made. Inside, there are many thin copper strands. Each strand has its own insulation layer. Workers twist or braid the strands in patterns. This helps current move through all the strands. The current does not just flow on the outside. The design spreads the current and keeps the wire cool.

Copper is the most used strand material. Copper lets electricity move very well. The insulation is often a polyurethane-nylon film. This film keeps strands apart and helps with soldering. The table below lists the main materials and their good points:

| Material Type | Material Used | Advantages |

|---|---|---|

| Strand Material | Copper | Great at carrying electricity; thin strands help stop skin effect losses because they are smaller than skin depth |

| Insulation Material | Polyurethane-nylon film | Keeps strands apart; easy to solder; lowers electromagnetic resistance from proximity effect; lets workers twist or weave strands to lower resistance more |

Litz wire can be round or rectangular. Round litz wire is used most often. Rectangular litz wire fits better in small or odd spaces. Some litz wire has a textile serve, which is thread wrapped around it. The serve protects the insulation and makes the wire stronger. But, it can make the wire harder to bend.

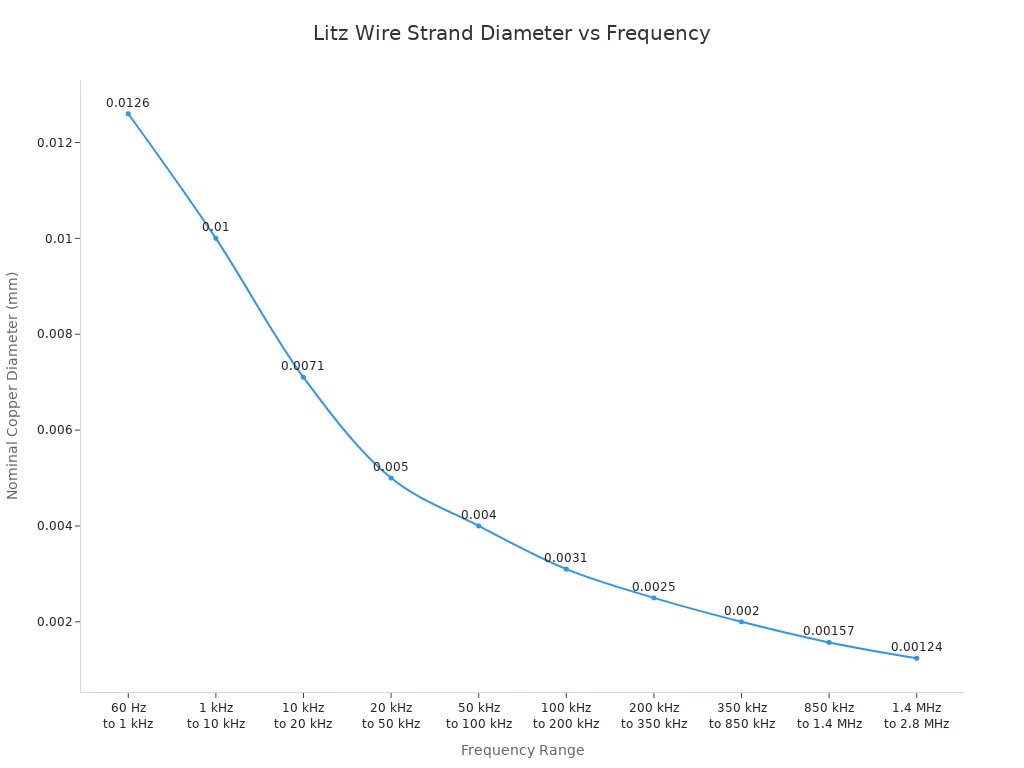

The way litz wire is built helps fight the skin effect and proximity effect. Many insulated strands keep high frequency currents from staying at the surface. This design lowers AC resistance and saves energy. Litz wire works best from 20 kHz to a few MHz. In this range, skin effect and proximity effect are big problems for solid wires.

Note: Litz wire can cut AC resistance by up to 70% compared to solid wires at high frequencies. This makes it a great pick for transformers, inductors, and wireless power systems.

There are many types of litz wire. The main difference is how many strands and how thick they are. Some litz wire has ten strands. Others have over a thousand. More strands lower AC resistance, but too many can raise proximity losses. Thicker strands help with skin effect losses, but may not fit everywhere.

Litz wire can be made for each job. Engineers choose the strand count, size, insulation, and diameter. These choices change how bendy the wire is, how much heat it can take, and how well it blocks electromagnetic interference. Litz wire types include:

Simple twisted litz: Just twisting insulated strands together.

Bunched litz: Groups of strands twisted, then twisted again.

Rope litz: Bundles twisted together like a rope.

Formed litz: Strands shaped into flat or rectangle bundles.

Each type is best for certain jobs. Rope litz is strong and bends easily. Formed litz fits in small spaces. Engineers use computer models to pick the best litz wire for each frequency and job. This helps lower losses and make motors, transformers, and circuits work better.

Insulation is very important in litz wire. Every strand has a coating. This coating stops the strands from touching and shorting. The insulation you pick changes how the wire works and how long it lasts.

Polyurethane and polyamide coatings are common. They are easy to solder and block electricity well. Polyurethane also stands up to chemicals and salt water, so it is good for ships. Polyester-imide and polyimide coatings handle heat better, but can soak up water.

Some litz wire uses fiber insulation. Cotton fiber is cheap and tough, but cannot be soldered and does not pack tight. Nylon fiber is strong and can be soldered, but it soaks up water. Dacron fiber stands up to heat and rubbing. Nomex and glass fiber work at high heat, but cannot be soldered.

Engineers sometimes add a serve, which is a nylon or silk layer. This serve makes the wire more flexible and helps it soak up varnish. Extruded coatings like ETFE give extra protection from water and chemicals.

The best insulation is tough and blocks electricity well. Good insulation keeps litz wire safe from damage, heat, and wear. It also helps the wire last longer in hard jobs.

Litz wire is used in many high-frequency jobs. Engineers put it in charging columns and high frequency transformers. It is also in inverters for solar panels and motors in electric cars. These jobs need wires that can handle fast currents. Litz wire helps stop energy loss. It lets current move through the whole wire, not just the outside. This makes devices work well up to 1 MHz. The twisted strands and special insulation lower electrical losses. They also help keep things cool. New shapes, like rectangular litz, and better insulation make it work even better.

Some high-frequency uses for litz wire are:

Charging columns

High frequency transformers

Inverters for solar panels

Motors in electric or hybrid cars

Litz wire helps these devices last longer and use less energy by cutting waste.

Transformers and inductors often use litz wire to work better. The many thin, insulated strands let current flow evenly. This design lowers AC resistance and heat. It also saves energy. In high-frequency inductors and big transformers, litz wire keeps the magnetic field balanced. This cuts down on fringing and proximity losses. Devices with litz wire last longer and work better because they stay cooler. Many engineers pick litz wire for transformers and inductors in high frequency power circuits.

Power electronics need litz wire to work well. These circuits switch currents fast, which can waste energy in normal wires. Litz wire’s design lets it handle quick changes without getting too hot. It is used in inverters, converters, and other power control devices. The wire bends easily and is simple to install. This makes it a favorite for engineers building new power systems.

| Factor | Description |

|---|---|

| Strand Diameter | Should be less than one-third of skin depth at the needed frequency for best results. |

| Number of Strands | Depends on how much current and cooling is needed. |

| Construction | Good twisting and bunching help lower losses. |

| Insulation & Thermal | Changes how reliable and heat-proof the wire is. |

| Packing Factor | Affects how much copper fits and the wire’s size. |

Litz wire is used in radio frequency (RF) gear and some audio devices. In RF coils, it helps find weak signals by lowering skin effect and making coils work better. Tests show litz wire can boost frequency response and cut losses in RF circuits. In hi-fi audio, the benefits are not as clear. Most experts say litz wire only helps at very high frequencies, above 100 kHz. For normal audio, cable shielding and capacitance matter more than the wire type. Still, litz wire is important for RF and special audio jobs where every bit of performance matters.

Litz wire is known for being very flexible. It has many thin, insulated strands twisted together. This makes it easier to bend than solid-core or normal stranded wires. Litz wire can fit into small spaces and different shapes. Installers can move it through tricky equipment more easily. The thin strands do not get stiff or break after moving them a lot. This helps in places where wires need to move, like in factories. But each strand has enamel insulation. You need special tools and skills to remove this for soldering. Handling Litz wire during assembly is harder than with regular wire.

Litz wire uses insulation that can take high heat. Most Litz wire can handle about 155°C (311°F). This matches Class F insulation. Polyurethane with a polyamide coat is used a lot for Litz wire. It works well for radio frequency jobs and does not cost too much. Regular magnet wire can take even more heat, up to 240°C, if it uses polyester insulation. Litz wire insulation is strong enough for most high-frequency uses. But it may not work in the hottest places. The insulation must last a long time at its rated heat. Picking the right insulation is important for safety and how well it works.

Litz wire costs more than normal wire. The price is higher because making it takes more steps. Each strand needs its own insulation. The strands must be twisted or woven together. Special materials and careful work add to the cost. The price can be a few dollars or even tens of dollars per meter. This depends on the design. More electric cars, green energy, and telecom make the price go up too. Litz wire design is tricky, especially for big jobs. Engineers must pick the right strand size and twist pattern. It is harder to control heat inside the wire because of all the strands and insulation. These things make Litz wire less easy to use than solid wire, especially for high current or special needs.

Note: Litz wire works great for high-frequency jobs, but people must think about the higher cost and tricky design before choosing it.

The skin effect happens when alternating current (AC) flows through a wire. At low frequencies, the current spreads evenly across the wire. As the frequency increases, the current moves closer to the surface. This leaves the center of the wire carrying less current. The skin effect reduces the effective area for current flow and increases resistance. For example, in copper at 60 Hz, the skin depth is about 8.5 mm. At higher frequencies, the skin depth becomes much smaller. At 10 MHz, most current in copper flows within just 0.066 mm of the surface.

The skin effect occurs because AC creates a changing magnetic field. This field produces eddy currents inside the wire. These eddy currents push the main current toward the surface. The current density drops quickly from the surface to the center. Engineers use the term "skin depth" to describe how deep the current flows. The skin depth depends on the frequency, the wire material, and its size. Higher frequencies mean a thinner skin depth and more resistance. This effect leads to more ac power loss and heat, especially in high frequency currents.

Tip: The skin effect is a big problem in radio-frequency circuits and power transmission. It can waste energy and make devices less efficient.

Litz wire helps solve the skin effect problem. It uses many thin, insulated strands twisted together. Each strand is smaller than the skin depth at the target frequency. This design lets current flow through the whole wire, not just the surface. The result is lower resistance and less ac power loss.

Researchers have tested Litz wire in many ways:

Simulations show that Litz wire spreads current more evenly than solid wire.

Measurements prove that Litz wire keeps ac resistance low up to a certain frequency.

Charts and graphs show that Litz wire reduces skin effect and eddy current losses, especially at high frequencies.

Visual tests reveal that coils made from Litz wire have a more uniform current flow.

Litz wire works best for high frequency currents, such as those in transformers, inductors, and wireless chargers. By reducing the skin effect, Litz wire helps devices run cooler and last longer.

Litz wire has lots of thin, insulated strands. These strands help stop energy loss from the skin effect. This makes litz wire work better at high frequencies. Experts say litz wire has some big benefits.

It saves energy and helps make small, efficient devices.

It is good for electric cars, transformers, and power electronics.

It costs more and needs people who know how to use it.

Engineers should do a few things.

They should use tools to pick the right strand size.

They should buy litz wire from trusted suppliers.

They should ask experts for help with special projects.

Litz wire has lots of thin, insulated strands twisted together. Regular wire is just one solid or stranded piece. Litz wire helps stop energy loss at high frequencies. This design lets current move better and keeps things cooler.

Litz wire works best for AC, especially at high frequencies. For DC, solid or normal stranded wire works fine. Litz wire does not give extra help for DC.

Tip: Take off the insulation from every strand before soldering. Use a solder pot or special tools to strip the enamel. Twist the strands together, then put on solder. This makes a strong and safe connection.

Many electronics stores and wire companies sell Litz wire. Online shops like Digi-Key, Mouser, and Allied Electronics have many choices. Always check the details before you buy.