English ![]()

Tel: +86-13732621090

Email:yewu001@yushengdz.com

4F, No.68, Huian Road, Xukou Town, Wuzhong District, Suzhou, Jiangsu, China, 215105

Views: 0 Author: Site Editor Publish Time: 2023-11-20 Origin: Site

Bare copper wire and enameled copper wire are two common types of conductors widely used in electrical and electronic industries. The main difference lies in whether they are covered with an insulating layer.

Definition: Bare copper wire refers to pure copper wire that has no insulation or coating. It is typically produced by drawing copper through a wire-drawing process.

Characteristics:

Excellent conductivity: Without an insulation layer, bare copper wire has extremely high conductivity.

High flexibility: Bare copper wire is commonly used in power transmission, grounding systems, and electrical equipment.

Prone to corrosion: Since it lacks a protective layer, bare copper wire is susceptible to oxidation and corrosion, requiring appropriate usage environments or additional treatment.

Applications:

Power grounding systems

Internal and external wiring for electrical equipment

Multi-strand wires in cables

Definition: Enameled copper wire is a copper wire coated with a layer of insulating enamel, which can be made of materials such as polyester, polyurethane, or polyimide, providing insulation and heat resistance.

Characteristics:

Good insulation performance: Enameled wire offers excellent insulation, preventing short circuits in compact electromagnetic devices.

Heat resistance: Thanks to its enamel coating, enameled copper wire maintains its insulating properties even in high-temperature environments.

High mechanical strength: Enameled wire has good abrasion resistance and tensile strength.

Applications:

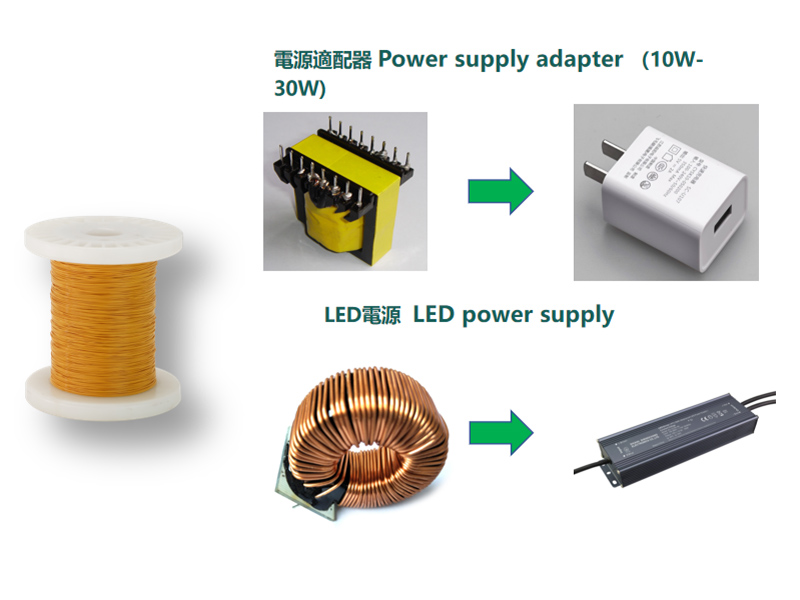

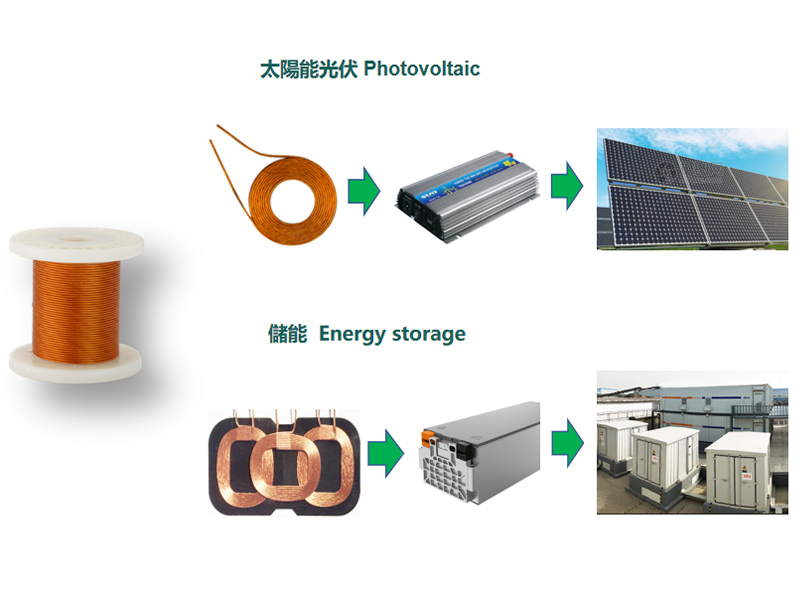

Winding electromagnetic coils in motors, transformers, and inductors

High-density circuits in various electrical devices

Coils in electronic and communication equipment

|  |  |